Ball mills are widely used in industries such as mining, cement, and metallurgy for grinding and blending materials. The grinding process involves the rotation of a cylindrical shell filled with grinding media, such as steel balls or ceramic beads. However, the continuous impact and abrasion from the grinding media can cause significant wear and damage to the mill shell over time. This is where ball mill liners play a crucial role.

What’ Ball Mill Liners

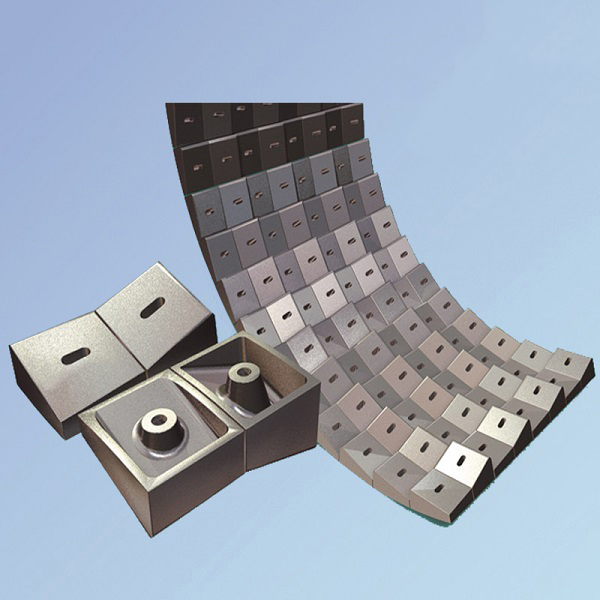

Ball mill liners are protective linings that are installed inside the mill shell to protect it from wear and damage. They are designed to enhance the efficiency of the grinding process and extend the lifespan of the mill shell. These liners are typically made of rubber, metal, or composite materials and are strategically placed to cover the inner surface of the mill shell.

Protecting the Mill Shell

The primary function of ball mill liners is to protect the mill shell from the intense wear and impact caused by the grinding media. As the mill rotates, the grinding media cascade and tumble inside the mill, generating a significant amount of force. Without proper protection, this force can lead to abrasion, erosion, and even structural damage to the mill shell.

Ball mill liners act as a protective barrier, absorbing the impact and reducing the wear and tear on the shell. They provide a sacrificial layer that can be easily replaced when worn out, preventing costly repairs or shell replacements. By safeguarding the mill shell, liners contribute to the overall longevity and reliability of the ball mill.

Benefits of Ball Mill Liners

- Wear Resistance: Ball mill liners are designed to withstand the abrasive nature of the grinding process. They are engineered to resist wear and minimize the impact of the grinding media, ensuring prolonged shell life.

- Impact Protection: The liners absorb the impact energy generated by the grinding media, reducing the risk of shell damage. This impact protection helps maintain the structural integrity of the mill shell.

- Noise Reduction: Ball mill liners made of rubber or composite materials can help reduce the noise generated during the grinding process. This is particularly beneficial in environments where noise control is a concern.

- Improved Grinding Efficiency: By protecting the mill shell and optimizing the impact of the grinding media, liners contribute to improved grinding efficiency. This leads to better particle size distribution and higher overall productivity.

Regular Maintenance and Replacement

To ensure the effective protection of the mill shell, regular inspection and maintenance of ball mill liners are essential. Over time, liners can become worn or damaged, compromising their protective capabilities. It is important to monitor the condition of the liners and replace them as needed to maintain the integrity of the mill shell and optimize grinding performance.

Ball mill liners play a vital role in protecting the mill shell from wear and damage caused by the grinding media. They provide a protective barrier, absorbing impact and reducing overall wear on the mill shell. With their wear resistance, impact protection, and noise reduction properties, liners contribute to improved grinding efficiency and extended shell life.

If you’re interested in learning more about ball mill liners and how they can enhance the efficiency and lifespan of your grinding process, we invite you to visit our website. Discover how the right choice of liners can optimize your grinding operations and maximize productivity.

Don’t miss out on this opportunity to gain valuable knowledge and make informed decisions for your ball mill operations. Visit Anhui Xinma Foundry Technology Co., Ltd. website today and unlock the potential of ball mill liners!