In the field of ore processing, ball mill liners play a critical role in ensuring the efficient and safe operation of grinding mills. These liners are not only designed to protect the mill shell and its internal components but also contribute to optimizing the grinding process and enhancing the overall performance of the milling operation. This article explores the importance of ball mill liners in ore processing and highlights their key benefits.

Section 1: Wear Protection

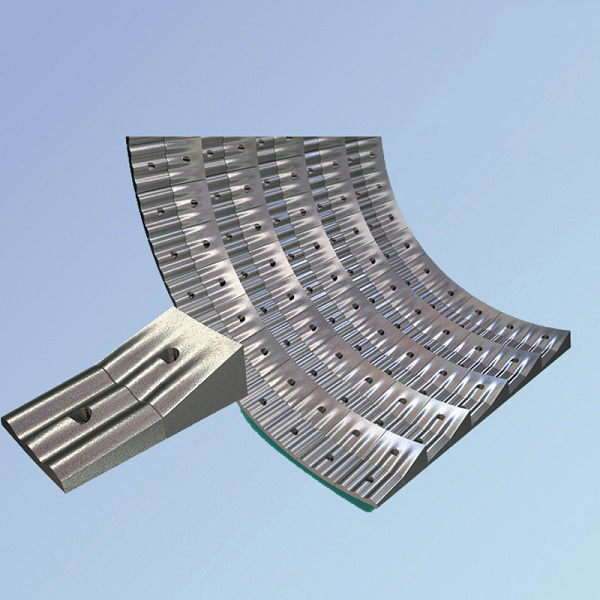

One of the primary functions of ball mill liners is to provide wear protection. Grinding mills are subjected to constant impact and abrasion from the grinding media and ore particles. The liners act as a sacrificial layer, absorbing the wear and tear and extending the lifespan of the mill. By protecting the mill shell and internal components, liners help minimize maintenance costs and downtime.

Section 2: Efficient Grinding

Efficient grinding is essential for maximizing the productivity of ore processing operations. Well-designed ball mill liners facilitate the movement of the grinding media and ore particles, promoting better grinding efficiency. They help to lift and tumble the ore, ensuring proper contact between the grinding media and the ore particles. This results in improved particle breakage and reduced energy consumption.

Section 3: Contamination Control

Contamination of the processed ore can have significant implications for the quality of the final product. Ball mill liners play a crucial role in minimizing contamination by preventing the mixing of different materials. They create a protective barrier that separates the ore being processed from the mill components, reducing the risk of unwanted chemical reactions or impurities. This ensures that the final product meets the required specifications and standards.

Section 4: Safety Enhancement

Safety is paramount in any industrial operation, including ore processing. Ball mill liners contribute to the safety of the milling operation by providing a protective barrier between the rotating mill shell and the surrounding environment. They help prevent accidents and injuries that may result from direct contact with the rotating components. By ensuring a safe working environment, ball mill liners contribute to the overall well-being of the operators and maintenance personnel.

Section 5: Ease of Maintenance

Maintenance plays a critical role in the smooth operation of ore processing plants. Ball mill liners are designed to be easily installed, removed, and replaced, simplifying maintenance procedures. This allows for quick inspections, repairs, and replacements, minimizing downtime and ensuring continuous operation. Easy maintenance of ball mill liners contributes to the overall efficiency and productivity of the milling process.

Section 6: Optimal Mill Performance

The selection of the right type of ball mill liners is crucial for achieving optimal mill performance. Factors such as liner shape, thickness, and composition can significantly impact the mill’s capacity, efficiency, and product quality. Properly designed liners help control the flow of ore and grinding media inside the mill, ensuring optimal contact and distribution for efficient grinding. By optimizing mill performance, ball mill liners contribute to the overall profitability of ore processing operations.

In conclusion, the importance of ball mill liners in ore processing cannot be overstated. These liners provide essential wear protection, facilitate efficient grinding, control contamination, enhance safety, and enable easy maintenance, all of which contribute to optimal mill performance. As a leading provider of high-quality ball mill liners, our website offers a wide range of options tailored to meet specific ore processing needs.

But our services don’t stop there. We also provide comprehensive wholesale and export services, catering to the global market. Whether you’re looking to equip your own ore processing plant or supply liners to other businesses, our expert team is ready to assist you. With our commitment to quality, reliability, and customer satisfaction, we strive to be your trusted partner in the ore processing industry.

Visit Anhui Xinma Foundry Technology Co., Ltd. website today to explore our extensive range of ball mill liners and learn more about our wholesale and export services. Experience the difference that top-notch liners can make in optimizing your ore processing operations. Trust us to deliver the solutions you need for enhanced efficiency, reduced costs, and superior product quality. Partner with us and take your ore processing to new heights.