Lab Test

SPECTROMETER

he whole digital spark source is controlled by computer. Through CCD detection technology and unique vacuum chamber, non-metallic elements C, P, S and various alloy components can be accurately measured, so as to achieve full spectrum analysis. This equipment has accurate measurement results and good long-term stability.

Main Technical Data

- Test matrix: Fe、Cu、Al、Ni、Ti、Co、Zn、Sn、Mg、Pb etc.

- Analyse wave band: 160-650nm

- Focal distance:400mm

- Grating line:3000/mm

- CCD pixel resolution:6pm

- Tungsten electrode material ejection electrode

- Analysis gap:4mm

- Excitation frequency: 100-1000Hz

IMPACT TESTING MACHINE

This machine is semi-automatic control testing machine, simple operation, high efficiency, swing, impact, discharge control. And the residual energy can be used for the next test preparation, especially suitable for continuous impact test in laboratory and a large number of impact tests in metallurgy, machinery manufacturing and other industries.

Technical Data:

- The impact of energy: 300J 150J

- The impact speed: 5.2m / s

- Pendulum horn angle: 150 °

- Sample bearing span: 40mm

- Bearing jaw round: R1.0 ~ 1.5mm

- Impact blade fillet: R2.0 ~ 2.5mm (R8mm)

- Pendulum center to the impact point distance: 750mm

- The standard sample size: 10 * 10 (7.5 or 5) *55mm

- Pendulum torque: M = 160.7695N.m 80.3848N.m

- Power and power: three-phase four-wire 50Hz 380V 250W

- Dimensions: 2200 * 650 * 1900mm

- Angle accuracy: 0.1 °

ROCKWELL HARDNESS TESTER

Function:

2. Dial can read HRA, HRB, HRC scale directly;

3. Adopt precision hydraulic buffer, feeding speed can be adjusted;

4. Pure mechanical manual detection process, no electrical control;

5. Widely used in production site quality control; Strong adaptability to working environment;

6. The accuracy conforms to GB/T230.2 ISO 6508-2 and ASTM E18 standard.

Technical Specifications:

- Measuring range :20-88HRA, 20-100HRB, 20-70HRC

- Test :588.4,980.7,1471 Newtons (60,100,150 kgf)

- Maximum allowable height of sample :170 mm

- Distance from center of pressure head to test wall :135 mm

- Hardness resolution :0.5HR

- Overall dimension (length * width * height):466 * 238 * 630mm

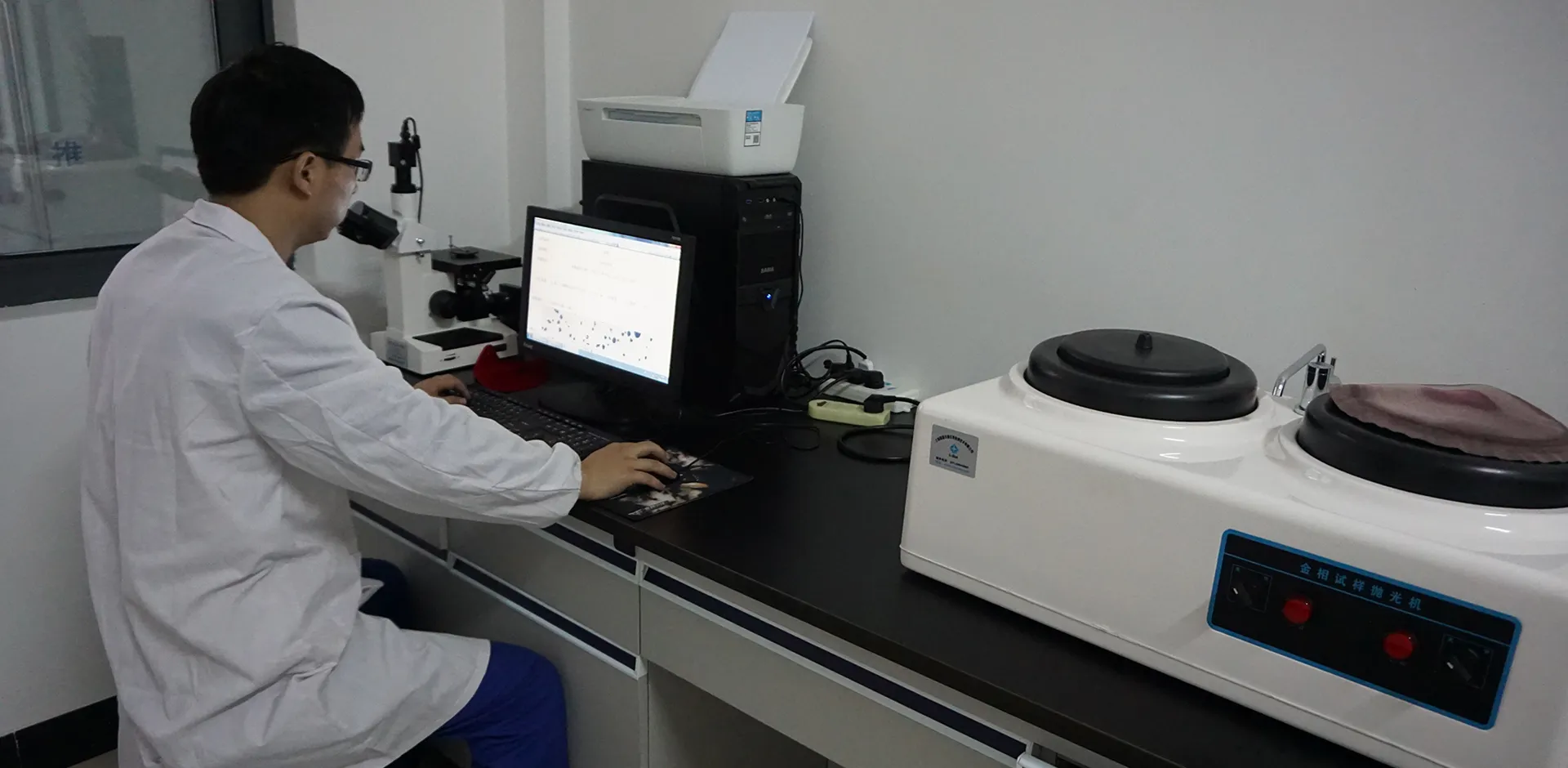

INVERTED METALLURGICAL MICROSCOPE

Metallographic premill

FALLING BALLS TESTING MACHINE

It mainly tests balls of the following sizes :Φ80, Φ100, Φ120, and only one type is checked at a time when testing, other transmission tubes should be closed.

- The fall distance is 3500mm.

- The number of falling balls is counted by the photoelectric sensor signal.

- Place the device on a flat ground; The power supply is 380V.

- One person is required to perform the check.

- The ball under test shall be smooth and without defect.

- Before power-on, the operator should add an appropriate amount of lubricating oil on the reducer and tighten all screws.

- In the machine, there are 16 grinding balls. If one of them is damaged, it should be picked up and another one added. If the test speed is fast, the operator should adjust by increasing the outlet weight.